Some Causes of Flange Leaks

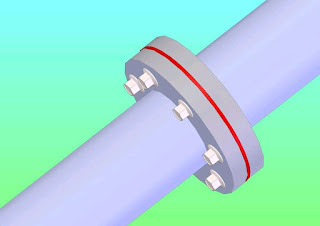

Flange leaks are a common issue in many industries, from oil and gas to chemical processing. They can cause significant downtime and safety hazards if not properly addressed.

Flange joint leaks can range from a barely detectable, slow emission or a sudden drastic failure. Both will cause severe problems for operators. Basic causes of Flange joint leaks are Fastener Fails, Gasket Fails and Flange Fails.

1. Fasteners Fails: Too tight or not tight enough? An incorrect "too-loose" assembly or loosening over time of fasteners can become a leak source. Conversely, fasteners that are too tight can put excessive loads on a gasket or increase fatigue on aging

equipment possibly causing stress cracking.

2. Gasket Fails: There is no way to predict when gasket failure will occur. Gasket manufacturers have these tips regarding bolted flange gaskets.

Selection:

Choose the right gasket for your application and conditions with an experts. An elastomeric based gasket can become brittle with elevated temperature or certain chemical conditions. If these gaskets

begin to leak a little, retightening may now cause them to break, resulting in a serious blowout situation.

Quality:

A lower priced gasket should not be the priority.

Reliability:

safety and gasket life are most important.

Installation:

Begin with knowledge of the correct Installation procedure. Using a torque wrench and knowing the correct torque values and tightening patterns/procedures are important to gasket longevity and performance.

3. Flange Damages: Warped surfaces can lead to improper installation. Flange surfaces can be damaged during transportation and installation, which could lead to poor performance.

First priority of an operator is the safety of personnel and the facility. Every reasonable effort must be made to ensure safety when it comes to potential leaks. Using protective shields to mitigate the effects of a leak can be done with Spray Shields,

sometimes called flange guards, flange wraps or flange protectors. These protective covers are used to inhibit leaks from spraying out to a wide area. Safety Spray Shields help to prevent injury to personnel, damage to nearby equipment and the environment

in the event of a spray-out of hot or dangerous liquids.